Modernizing Airport Signs:

LED Retrofits and TP312 Considerations

by Bulent Ulas

Airport Services Manager, Arc & Spark Electric

Published: December 2025

Last Revision: January 2026

At a Glance

- Illuminated signs can be retrofitted to LED without replacing the sign as a whole.

- LED sign upgrades can reuse existing airfield lighting infrastructure.

- TP312 compliance applies to the individual sign, not runway or taxiway wide.

- Retrofits don’t require compliance with the 5th edition, unlike replacements.

Why Airports Consider LED Upgrades for Illuminated Signs

Airports typically consider LED upgrades for illuminated signs as a way to improve reliability and maintain long-term compliance, rather than as a technology upgrade for its own sake.

Incandescent and halogen light sources gradually degrade over time. While signs may continue to illuminate, their luminance, colour consistency, and contrast can drift, making it increasingly difficult to remain within the photometric limits defined by current standards. This degradation is not always visible during routine inspections and may only become apparent during formal testing.

LED light sources offer a longer and more predictable service life. Their photometric performance remains more stable over time, allowing airports to maintain compliance with less uncertainty between inspections and fewer corrective interventions.

For some airports, obsolescence is an additional driver. Older illuminated signs, including legacy fibre-optic designs, often have limited or discontinued manufacturer support. Replacement parts, panels, or verified photometric performance data may no longer be available, increasing operational risk. LED retrofits provide a practical way to restore a supportable and testable system without replacing the entire sign assembly.

By upgrading the light source and, where required, the sign panels, airports can extend the useful life of existing sign structures. This supports a phased, asset-management-based approach to compliance and reliability, without forcing full sign replacement projects.

What an LED Sign Retrofit Involves

An LED retrofit of an illuminated airport sign focuses on upgrading the light source while retaining the existing sign structure wherever possible.

In most cases, the sign housing, mounting, and overall installation remain unchanged. The retrofit typically involves replacing the internal light source with LED modules designed to operate on existing airfield lighting series circuits. Where sign panels have degraded over time, panels can also be replaced to restore legibility and photometric performance.

LED retrofits are engineered to work with existing airfield lighting power supplies. Constant Current Regulators (CCRs) and the broader airfield lighting system architecture are normally left unchanged. The retrofit does not require modifications to the lighting vault or changes to intensity step control.

Once the retrofit is complete, the modified sign system must be verified through photometric testing to demonstrate compliance with the applicable TP312 requirements, confirming that luminance, colour, and contrast meet the standard.

TP312 Editions and Their Impact on Runway and Taxiway Signs (revised)

Canadian airports commonly operate airfield infrastructure designed to different editions of TP312. This is normal and acceptable, as airfield assets are installed, upgraded, or replaced over time rather than rebuilt as a single integrated project.

When an illuminated sign is replaced as a complete unit, the replacement sign must comply with the current edition of TP312. This requirement applies only to the specific sign being replaced and does not require upgrading other existing signs on the same runway or taxiway. The exception applies to mandatory instruction signs, for which TP312 requires a corresponding sign on the opposite side of the taxiway. In such cases, both signs must comply with the current edition.

This requirement is limited to the sign itself. It does not extend to other visual aids serving the same runway or taxiway. Markings, runway or taxiway lights, and other airfield lighting systems may legitimately continue to comply with the edition of TP312 under which they were installed or last modified.

By contrast, when an illuminated sign is retrofitted rather than replaced, the sign structure remains unchanged and only internal components—such as lamps and, where necessary, panels—are upgraded. Provided the sign box is not replaced as a complete assembly, the sign may continue to comply with the edition of TP312 under which it was originally approved, in accordance with Transport Canada AC 302-018.

As a result, it is entirely acceptable for a single runway or taxiway to operate with a mix of TP312 editions across different systems. For example, a runway may have:

- an illuminated sign compliant with the 4th Edition,

- another illuminated sign compliant with the 5th Edition,

- markings compliant with the 4th Edition, and

- runway edge lights compliant with the 5th Edition,

without creating a compliance conflict.

This system-based application of TP312 allows airports to plan upgrades in a targeted and phased manner while maintaining regulatory compliance.

Sign Locations and Quantity Considerations Under Different TP312 Editions

Location

In most cases, upgrading illuminated signs to LED does not require relocating them. For signs originally designed to the 4th Edition of TP312, the location requirements in the 5th Edition are largely unchanged, and existing placements are generally acceptable.

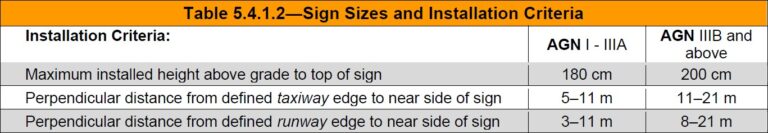

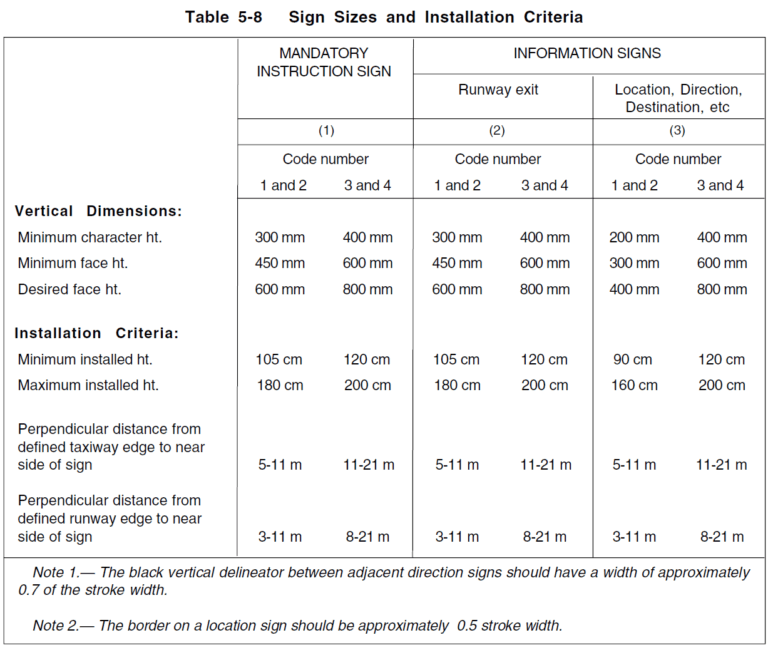

Meaningful location differences arise primarily for signs designed to the 3rd Edition of TP312. Under the 3rd Edition, illuminated signs were required to be installed 15 metres from the edge of a runway or taxiway. The 5th Edition, for AGN I, II, and IIIA, specifies a maximum distance of 11 metres from the runway or taxiway edge. This represents a 4-metre difference.

Where a location adjustment is required, the impact is typically limited. Relocation usually involves moving the sign closer to the runway or taxiway edge rather than changing the overall sign system serving that runway or taxiway. From an infrastructure and electrical perspective, this often translates into a short extension of existing ducting and standard airfield lighting circuit work, rather than major civil works or changes to the airfield lighting system.

Quantities

The 5th Edition introduces changes related to sign quantity in certain configurations. Under the 4th Edition, smaller airports were permitted to use a single sign for some locations. The 5th Edition removes this distinction and requires two signs for the same configurations, regardless of runway or taxiway category.

Applicability

Where this requirement applies, it only affects the runway or taxiway whose signs are being upgraded to comply with the 5th Edition. It does not extend to other runways, taxiways, or unmodified sign systems. If meeting the updated sign quantity requirement would involve additional infrastructure work, airports may choose to defer that runway or taxiway and proceed with upgrades elsewhere. This allows sign upgrades to be phased and planned without forcing immediate, airfield-wide changes.

Key Takeaways for Airport Operators

- LED upgrades of illuminated signs can usually be completed through retrofit without replacing the sign structure or modifying airfield lighting power systems.

- Retrofitting an illuminated sign (lamp and/or panel replacement without replacing the sign box) is not considered sign replacement and does not require compliance with the latest edition of TP312.

- When an illuminated sign is replaced as a complete unit, only that specific sign must comply with the current edition of TP312; replacement does not, by itself, require upgrading other existing signs on the same runway or taxiway.

- An exception applies to mandatory instruction signs, where TP312 requires a corresponding sign on the opposite side of the taxiway; in such cases, both signs must comply with the current edition.

- Incandescent, halogen, and legacy fibre-optic signs become increasingly difficult to keep compliant over time, even if they remain illuminated, due to gradual photometric degradation.

- Most signs installed to the 4th Edition of TP312 do not require relocation when retrofitted; however, signs originally designed to the 3rd Edition may require modest location adjustments under the 5th Edition.

- Different airfield subsystems—including signs, markings, and runway or taxiway lighting—may legitimately comply with different editions of TP312 on the same runway or taxiway.

- Sign upgrades can be planned and phased on a sign-by-sign basis, allowing airports to manage compliance, cost, and operational impact without forcing airfield-wide upgrades.

References

- Aerodrome Standards and Recommended Practices (TP312), 5th Edition

- Aerodrome Standards and Recommended Practices (TP312E), 4th Edition

- Aerodrome Standards and Recommended Practices (TP312E), 3rd Edition

- AC 302-018 – Grandfathering at Airports Pursuant to Canadian Aviation Regulation (CAR) 302.07

Revision History

- December 2025: Initial publication.

- January 2026: Update and correction of TP312 applicability to illuminated signs

This article was updated to clarify the application of TP312 requirements to illuminated sign upgrades. The original text stated that upgrading signs on a runway or taxiway would require all signs serving that movement area to comply with the current edition. This has been corrected. In accordance with Transport Canada Advisory Circular AC 302-018, compliance with the current edition of TP312 applies to individual signs when they are replaced as complete units. Where signs are retrofitted without replacement of the sign box, they may continue to comply with the edition under which they were originally approved.